The drone industry is rapidly advancing technologically and expanding in its applications, but it also faces significant challenges and responsibilities. As drones are being used in more locations and more frequently, they are becoming increasingly commonplace. However, we should remember the safety risks they can create if not designed and operated with safety in mind.

Although implementing safety programs is not my area of expertise, I wanted to raise this topic to promote discussion. It is becoming more and more apparent that a safety culture is necessary for the responsible use of drones.

Drawing parallels with the established safety culture of the aviation industry, I’ll explore the importance of incorporating similar practices within drone operations, design, and manufacturing. But first, let’s define what safety culture means:

Understanding Safety Culture in Drone Operations

Safety culture refers to the attitudes, beliefs, behaviors, and values of employees regarding safety. A strong safety culture is vital because it promotes greater awareness and proactive management of potential hazards throughout the process.

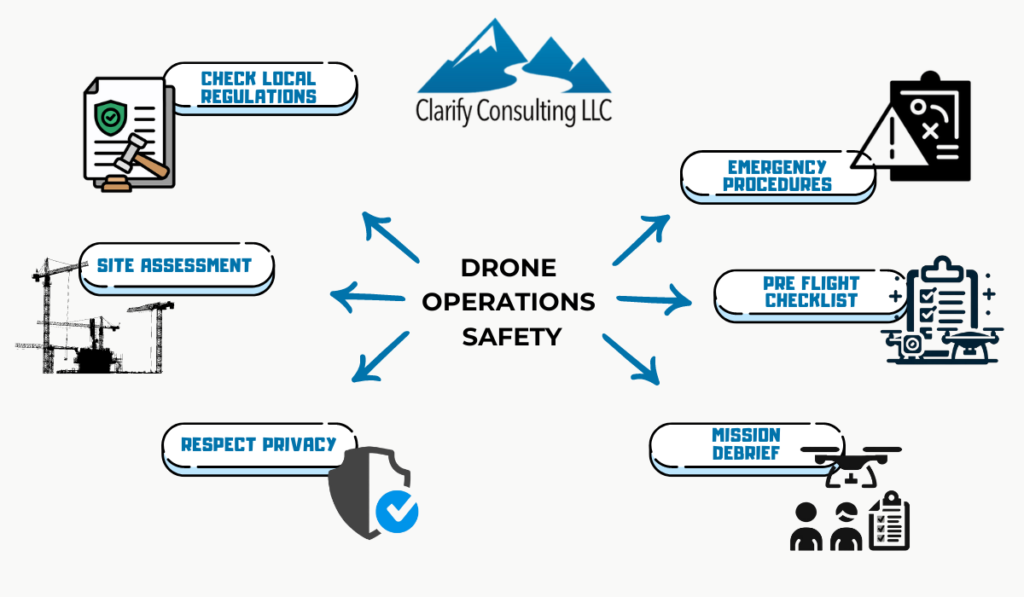

In the manned aviation sector, an embedded safety culture minimizes risks and enhances operational efficiency—a model that drone operations can emulate. Formal site assessments, checklists, written procedures, policies, training, and internal or external qualifications can be fundamental in building and maintaining that safety focus.

For instance, commercial airlines conduct regular safety drills and pilot assessments to ensure high standards—a practice that can be adapted to drone pilot training and protocols. While some operators fly “fast and loose,” others rigorously follow aviation-style checklists. Finding the right balance ensures safety is highly valued by customers who also prioritize it.

The FAA, which has long been safety-centric, recently held a Drone Safety Day to highlight the need for a safety culture within the drone operations community. You can download their play book here.

Safety in Drone Design and Manufacturing

Drone safety begins with design and manufacturing. Drones built to high safety standards reduce the risk of accidents or malfunctions that could compromise safety. The Federal Aviation Administration (FAA) in the U.S. and the European Aviation Safety Agency (EASA) provide guidelines for manufacturers undergoing certification, but it is often up to manufacturers to set their standards, focusing on material quality, electronic integrity, and fail-safe features.

There is a solid business case for drone equipment OEMs to prioritize safety as a core feature. Industrial users generally value safety and appreciate equipment and operations that meet stringent standards. Industries like oil and gas, utilities, mining, railroads, and large-scale construction have strong safety cultures and expect equipment and contractors operating near their assets to be safe.

OEMs that provide enhanced safety features compared to their competitors will likely see greater adoption of their products.

Implementing a Safety Culture in Drone Companies

To cultivate a safety culture, drone companies must consider it a core part of their corporate identity. This starts with leadership, as executives and managers must consistently demonstrate their commitment to safety, integrating it into all business decisions. Practical steps include:

- Incorporating safety considerations into design reviews

- Evaluating prototype builds for safety standards

- Conducting comprehensive site assessments

- Including safety in operational mission planning

- Providing regular safety training for operations teams

- Investing in reliable equipment for operations teams

- Creating open communication channels for safety concerns

- Conducting periodic audits and using feedback loops

Periodic audits and feedback loops can identify potential risks before they cause incidents, reinforcing a culture of safety. Safety standards and risk mitigation should be considered during the design phase and assessed in testing.

Challenges and Solutions in Drone Safety Culture Adoption

Establishing a safety culture in a rapidly evolving industry like drones involves challenges such as resistance to change, cost implications, and scalability issues, especially for smaller companies.

One primary challenge is resistance to change among employees, who may see new safety protocols as burdensome or unnecessary. Management must prioritize communication to clearly explain the benefits of these measures for the company, employees, and customers. Involving employees in planning and implementing safety measures fosters a sense of ownership and acceptance.

A lack of adequate resources—time, money, or training—can hinder the establishment of a safety culture. Businesses should allocate specific budgets for training and equipment and schedule regular sessions to ensure that all employees are competent and confident in safety practices.

Consistent enforcement of safety policies is crucial. This can be achieved through regular audits, feedback loops, and leading by example, ensuring that safety becomes a core component of the company’s values.

The Role of Third-Party Certifications in Enhancing Safety

Third-party certifications can play a crucial role in enhancing safety culture in the drone industry by providing independent assessments of compliance with safety standards. They serve as benchmarks for safety and quality, reassuring clients and regulatory bodies about the reliability of the drones and operations.

Organizations like the International Organization for Standardization (ISO) and several other private organisations offer guidance and/or certifications that assess pilot training, maintenance, and operational safety protocols. These certifications are valuable because they validate adherence to high safety standards while enhancing the company’s credibility and marketability.

Third-party certifications encourage companies to stay updated with the latest safety innovations and regulatory changes, ensuring that they remain at the forefront of best practices. They also promote transparency and accountability, which are vital for a strong safety culture. By pursuing these certifications, drone companies demonstrate their commitment to safety and differentiate themselves in a competitive market, emphasizing their focus on both performance and the well-being of their clients and the public.

Advancing the Future of Drone Safety

While I don’t claim to be a safety management expert, my nearly 15 years of experience working with drone manufacturing, engineering and operations teams have shown me that establishing a strong safety culture in the drone industry is not just beneficial but imperative for ensuring operational integrity, public trust, and increased access to airspace.

As the industry grows, adopting rigorous safety protocols similar to those in aviation is crucial. OEMs and service providers must lead by example, championing safety initiatives that protect their assets, customers’ assets, and the public. This proactive approach not only safeguards personnel and equipment but also fortifies public trust and the industry’s reputation.

I’m always open to discussing this and any other topics in depth. I’m keen to hear your thoughts in the comments below, or let’s have a chat!